Item No :

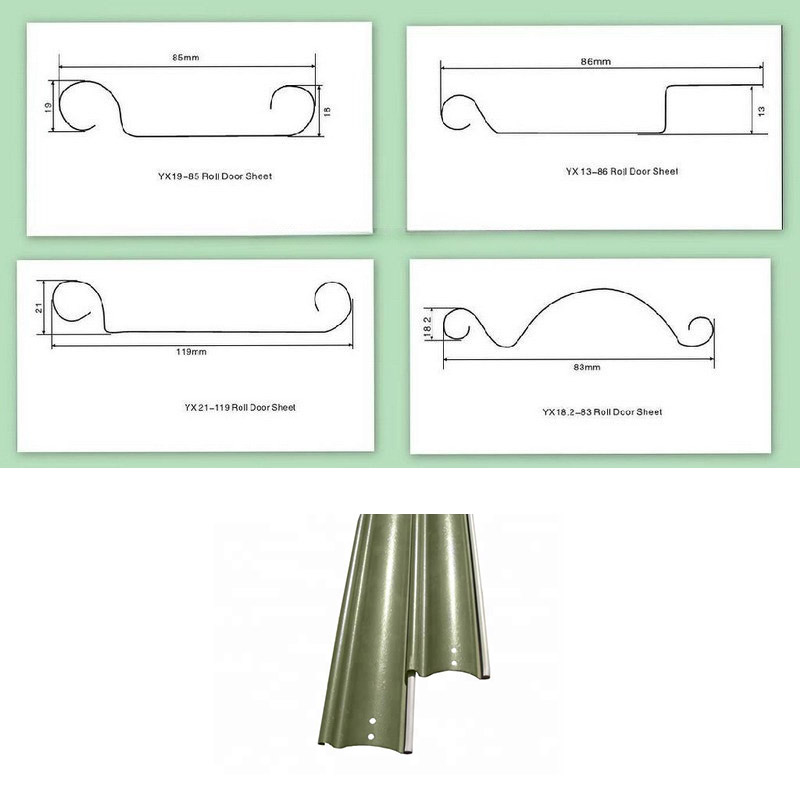

YX14-85Order(MOQ) :

1Payment :

ttProduct Origin :

chinaColor :

Blue/greenShipping Port :

shanghaiLead Time :

40dayWeight :

11TosBasic information

De-coiler—→level device—→main roll forming machine—→ hydraulic cutting—→ run out table

Machine component

3T Manual De-coiler

Diameter: 460-520mm expansion.

Expansion: Manually

Capacity: 3000kg

Leveling device

1.7 rolls leveling, 3 rolls up and 4 rolls down

2.Diameter is Ø 70mm, chrome and HRC60 heat treatment to secure the smooth surface

3.Max Leveling Raw Material width: 300mm

Hydraulic station

1. hydraulic station pressure: 12MP

2. power of hydraulic station: 4KW

Hydraulic Cutting

1. The cutter blade material: Cr12mov HRC58-62 degree

2. Blades number: 2 sets

3. Cutting after forming: Cut the sheet after roll forming to required length

4. Cutting motion: The main machine automatically stops and the cutting will take place. After the cutting, the main machine will automatically start.

5. Material of blade: CR12with heat treatment

6. Length measuring: Automatic length measuring

7. Tolerance of length: 6m+/- 0.5mm

Control Box

(1)Power supply: 380 V, 50 Hz, 3Phase (adjusted with the requirement)

(2)Length & quantity measurement automatically;

(3)Length & quantity controlled by PLC,

(4)Length inaccuracy can be amended easily.

(6).Control panel: Button-type switch and touch screen

(7)Unit of length: millimeter (switched on the control panel)

1、The warranty is 24 months after the client receives the machine. Within the 24 months, we will courier the

replacement parts to the client free of charge.

2、We offer technical support for the entire life of our machines.

3、We can sent our technicians to install and train the workers in the clients' factories with extra cost.

Main body of machine is naked and covered by plastic film ( to protect of dust and corrosion), loaded into container

and steadily fixed in container suitable by steel rope and lock, suitable for long-distance transportation.

FAQ

A:- What is your payment term?

- 30% of the total payment should be paid as deposit ,the balanced should be paid after check the finished photos

and videos well ,we supply test report.

B:- Can you finish the machine during the delivery time?

- We will finish the machine in time according to determined lead time.

C:- Can you provide some spare parts?

- Yes, of course. The quick-wear parts are sent to you together with the machine.

D:- What is the after- sale service?

- 24 months from time of loading by seller quality guarantee, life guarantee repair.

Within quality guarantee period, except for failures caused by human error, repair parts will be provided for free.

After the quality guarantee period, only charge the production cost of the spare parts.Free technical supporting and

maintenance consulting in lifetime.Within quality guarantee period, except for failures caused by human error, repair parts

will be provided for free. After the quality guarantee period, only charge the production cost of the spare parts.Free technical

supporting and maintenance consulting in lifetime.

E:-Can you accept OEM?

- We can accept OEM

Related Products

curving machine flatttening cutting machine Floor Decking Folding machine Purline Machine Rolling shutter Roof Machine Standing Seam Roof Machine

Water guttar machine

Tags :